The oil & gas industry isn’t alone when it comes to preaching the importance of safety on the job. Call them what you will, accidents, mistakes, carelessness or just plain incidents, they still occur. The results can be catastrophic. Something the oil industry knows very well.

- February 15, 1982: Newfoundland, Canada. The offshore oil rig Ocean Ranger was struck by a rogue wave off the coast of Newfoundland and sank with the loss of all 84 crew.*

- March 23, 2005: Texas City Refinery explosion. An explosion occurred at a BP refinery. It is the third largest refinery in the US and one of the largest in the world. Over 100 were injured, and 15 were confirmed dead. BP has since accepted that its employees contributed to the accident.*

- December 11, 2005: Hertfordshire Oil Storage Terminal fire. A series of explosions at the Buncefield oil storage depot, described as the largest peacetime explosion in Europe. There were no fatalities. Total damages have been forecast as $1,480,060,731 CAN.* An investigation determined a management failing in that systems were in place but they were both deficient and not properly followed.**

- April 20, 2010: Deepwater Horizon oil spill in the Gulf of Mexico. 11 oil platform workers died in an explosion and fire that resulted in a massive oil spill in the Gulf of Mexico.* A report by the US Oil Spill Commission said there had been “a rush to completion” on the well. “There was not a culture of safety on that rig,” the co-chair said. ***

- July 6, 2013: Lac-Mégantic Quebec derailment. 47 people were killed when there was a derailment of an oil shipment train. The oil caught fire and exploded, destroying more than 30 buildings. The railway line was owned by the US-based Montreal, Maine and Atlantic Railway (MMA). In its investigation, the Transportation Safety Board found a number of preventable issues contributed to the disaster, one is described as a weak safety culture. *

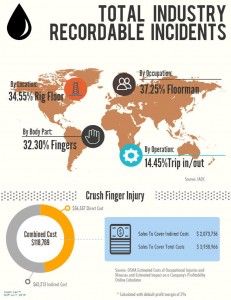

Not all in incidents/accidents are catastrophes. As this graphic by the US Occupational Safety & Health Administration shows. One thing is certain, all injuries take a toll, whether they are personal or financial. When it comes to injuries in the oil industry, the majority happen on the rig floor and one third involve hands. Being pro-active instead of re-active can protect workers and save lives as well as improve a companies bottom line.

Not all in incidents/accidents are catastrophes. As this graphic by the US Occupational Safety & Health Administration shows. One thing is certain, all injuries take a toll, whether they are personal or financial. When it comes to injuries in the oil industry, the majority happen on the rig floor and one third involve hands. Being pro-active instead of re-active can protect workers and save lives as well as improve a companies bottom line.

Take the first step and call Katch Kan. We protect lives and Mother Earth. The Rig Safety System protects workers while our Zero Spill System ensures the environment is protected from being contaminated.

Safe, healthy workers and a clean, protected environment saves companies in medical related bills, lost time and clean up charges. At the same time a more efficient production site increases profits. If that’s not enough all these benefits help improve your company’s reputation and the industry’s as well.

* from wikipedia

**from investigation by England & Wales Major Incident Investigation Board, the Health and Safety Executive and the Environment Agency

***BBC News