Business Case South Texas Well #

Oil companies now have an opportunity to maximize operational savings by getting their drilling contractors to cut down on excessive mud costs (drilling fluids) by using the Katch Kan™ Zero Spill System™.

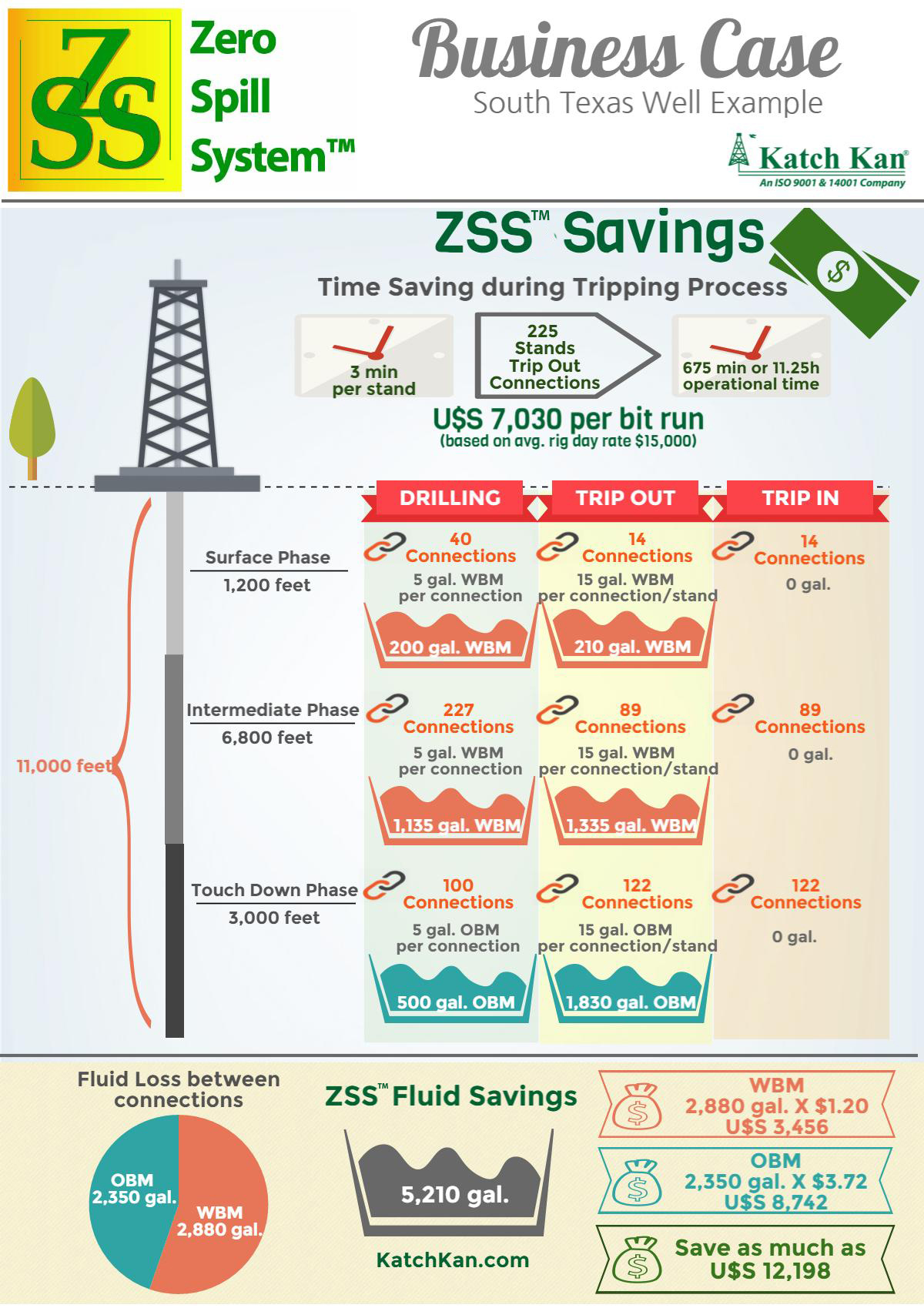

Time Savings During Tripping Process #

Our Clients have reported up to 3-minute savings per stand through using the Zero Spill System™, eliminating as much as 675 minutes in operational time or $7,030 (U$S) per bit run.

Mud Savings During Drilling Process #

Contractors lose 5 gallons of fluid or more making a connection and 15 gallons or more when tripping wet. Oil companies have the potential to capture fluid totaling as much as 5,210 gallons per single well. In terms of dollars and cents, this means an opportunity to save as much as $12,198 (U$S) in mud usage per job.

Connection and Mud Usage Calculations: #

Surface Phase: #

- Drill conductor to 1,200 feet = 40 connections at 5 gallonsWBM

- Trip out drill pipe at 1200 feet = 14 connections (stands) at 15 gallonsWBM

- Trip in 1200 feet of pipe = 14 connection at 0 gallons

Intermediate Phase: #

- Drill to intermediate at 8,000 feet = 6,800 feet = 227 Connections at 5 gallonsWBM

- Trip out drill pipe at 8,000 feet = 89 connections at 15 gallonsWBM

- Trip in drill pipe to 8,000 feet = 89 connections at 0 gallonsWBM

Touch Down Phase: #

- Switch over to OBM

- Drill toTD at 11,000 feet = 3,000 feet = 100 connections at 5 gallons OBM

- Trip out at 11,000 feet = 122 connections at 15 gallons OBM

Note: Water-BasedMud (WBM) was priced at $1.20 per gallon and oil-basedmud (OBM) at $3.72 per gallon.

Remediation & Reclamation Savings #

Oil companies can spend anywhere between $60,000 and $80,000 to reclaim a site back to zero footprint.