Environmental regulations are rapidly becoming global in the Oil and Gas Industry and more voluntary guidelines are changing from voluntary to mandatory with the consequently increase in Corporate Social Responsibility reporting.

The key differentiators between regulations around the world are the methods of enforcement, type of information available to the public like non-compliances, debt or infractions, fines and penalties, and different mechanisms of monitoring and reporting required during operations and after the end-of-life of the facility.

Some countries have more stringent regulations than others but all require environmental assessments and compliance with cleanup and remediation programs in place. The environmental footprint of a company plays an important role to determine in many cases, a security deposit or financial assurance and it has a direct impact on license approval or acquisition approval.

Costly cleanup could be easily managed and minimized with proactive solutions like the Zero Spill System.

The Zero Spill System prevents soil and water contamination by collecting the fluids used and released during the drilling process for subsequent reuse or recycling.

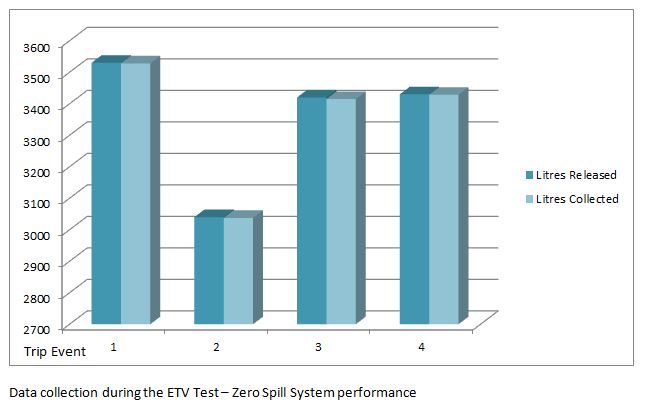

The performance of the Zero Spill System was proved and verified by the Environmental Technology Verification (ETV), the Zero Spill System collects 99.9% of the drilling fluids.

The use of the Zero Spill System not only saves time and money during the drilling process, but it also reduces cleanup costs after the end-of-life of the facility.

The spill containment system can be easily installed in drilling rigs, workover/service rigs, wellheads, barge rigs, as well as other applications.